Acoustical Design For Stages, Control Rooms, Video Editing Rooms & More

Whether you are planning to build a new studio from the ground up or doing an upgrade, proper lighting design is essential. Office, stage and post-production rooms each have different requirements.

Learn how sound works, how to prevent sound leakage between rooms, and acoustical properties overview.

Sound In the Real World

In nature, surfaces are very irregular with very few parallel surfaces for sound to reflect back and forth. So, the sound we hear outdoors is natural, without echoes and does not emphasize one frequency over another. Indoors, rooms reflect sound. The amount of sound reflected is determined by the shape and size of the room as well as the surfaces of the walls, floor and ceiling. Imagine you are in a large empty room with the floor and walls made of marble. These hard surfaces will reflect sound and create echoes.

On the other hand, if you were in a very small room with thick carpet, an acoustic tile ceiling and lots of furniture to break up the sound waves, the room would be echo free. In fact, it would sound similar to sound outside.

It is very easy to add echo and reverberation. Unfortunately, it is almost impossible to remove it. A correctly designed room should not emphasize or inhibit any frequencies. Therefore, stages should be designed to be as non-reflective (dead) as possible. That way, during post-production, the correct amount of reverberation can be added so that the sound is natural.

Control and editing rooms need to be non-reflective so that the sound that is heard is the same as what is being recorded or played back.

There are two areas of acoustical concern when designing video production facilities: the acoustical properties of the rooms and sound leakage between rooms.

Preventing Sound Leakage Between Rooms

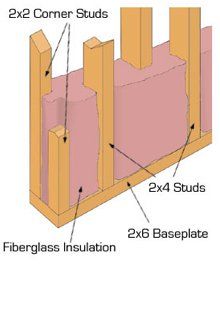

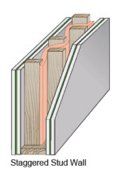

There are three methods to prevent sound leakage: absorption, mass and sound transmission avoidance. Sound transmits through the walls, floor and ceiling. Using staggered 2X4 studs within the walls nailed to 2X6 base plates is the standard way to insure that two adjoining walls do not have any common surfaces. The 2X6 base plates need to have a rubber gasket between the floor plate and the concrete floor. R19 insulation is inserted between the studs. Cutting groves in the concrete floor between the rooms also reduces transmission.

The walls need to have two layers of 5/8” drywall attached to both sides of the wall. This gives mass to the wall to help absorb high and low frequencies. The ceiling should be built in the same manner as the walls. HVAC ducts need to be installed with noise traps. Larger than normal ducts deliver adequate airflow at a lower velocity – thus reducing noise from the HVAC.

Acoustical Properties Within the Editing and Control Rooms

Poorly designed rooms result in poor sound that can be too dead or so reflective they become echo chambers. A well-designed control room will:

- Not emphasize any particular frequency. In other words it will have a flat response.

- Have a large “sweet spot” for stereo imaging. In other words, the stereo sound will not change much as the operators move from side to side.

- Not have any dead spots.

- Not reflect sound off the walls causing echoes.

These goals are achieved in two ways: correct room proportions and sound treatments on the walls. Below are the rules for correct room proportions:

- No two wall dimensions shall be divisible into each out. For example a 10’ by 10’ room would be horrible. If the ceiling was 10’ high, it would be even worse. The room would cause “standing wave reflections” resulting in “wave cancellations”. This would be experienced as dead zones with muddy, dull sound. A 10 X 20 room would be almost as bad. A 9X17 room would be good as there is no whole number that can divide into them. Likewise an 11’ by 15’ is acceptable. One must also factor in the height of the room. For example, a 12’ wide by 17’ length by 9’ high would be bad because the 12’ width and the 9’ height can be divided by 3

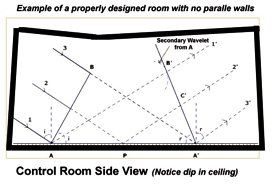

- No wall should be parallel in any plane. In other words, the walls should be tilted 2 or 3 degrees from each other top to bottom and left to right. The same goes for the floor and ceiling.

- The classic live end/dead end room is ideal. By this, we mean that one end of the room should have hard surfaces while the other end of the room should have soft sound absorbing surfaces (bass trap).

- Near the front of the room, the left and right wall’s should have “Helmholtz Resonators”. They are large pieces of pegboard with holes drilled into them to breakup sound waves.

- The ceiling should angle downward from the front of the room at approximately 15° for 1/3 of the distance of the total length of the room. It then should angle upwards at about 10° degrees for the last 2/3 of the length of the room.

Next we address wall treatments. Wall treatments are used to inhibit sound reflections and to trap low frequencies. Of course, one must be careful to not apply too many inhibitors, as the room can become dead and muddy sounding. Generally we construct the front of the room with hard surfaces to project the sound from the speakers towards the rear of the room.

At the rear of the room we have materials that trap sound so that it is not reflected back into the room creating noise cancellation. This is called a “Base Trap”. Along the sidewalls we apply acoustic foam sporadically.

Summary

Proper stage and control room design is 70% science and 30% art. Incorporating the fundamentals of proper design as specified in this article adds to the cost of building the rooms. However, correcting bad acoustics as a result of building a poorly designed room is way more expensive. That is why anyone planning to build a new stage or control room should hire an experienced designer who understands acoustic fundamentals.